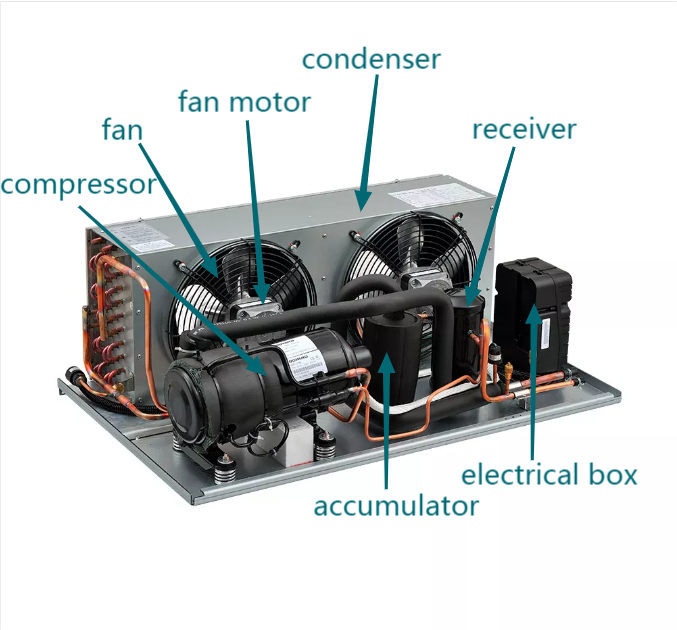

What’s included in Boyard common fixed speed indoor condensing unit?

Refrigeration compressor

https://www.zjboyang.com/refrigeration-compressor

This series of Compressor,light weight, low noise, high efficiency, low discharge temperature, long operation life and are able to work under wide voltage. It’s widely used for supermarket cabinet, air curtain cabinet and other commercial refrigeration & freezing equipment.

The Boyard compressor is a popular choice for commercial refrigeration and freezing equipment, such as supermarket cabinets and air curtains. These compressors are known for their lightweight design, low noise, high efficiency, low discharge temperature, long service life, and ability to operate under a wide voltage range.

The lightweight design of the refrigeration compressor series makes it easy to install and maintain. Its low noise operation ensures a comfortable environment for customers and staff. Moreover, the high efficiency of these compressors means that they consume less power, contributing to cost savings and environmental sustainability.

The refrigeration compressor series also features a low discharge temperature, which reduces the risk of overheating and prolongs the lifespan of the compressor. Additionally, these compressors are engineered to withstand a wide voltage range, making them suitable for use in various locations and conditions.

The Boyard compressor has a refrigeration capacity of 1-3 horsepower (hp). If the required refrigeration capacity is less than 1 hp or greater than 3 hp, piston or rotary compressors can be purchased externally.

Overall, the refrigeration compressor series is a reliable and efficient choice for commercial refrigeration and freezing equipment. Its long service life, low noise, and energy-saving capabilities make it an ideal solution for businesses seeking to improve their refrigeration and freezing systems while reducing operating costs.

Condenser

Boyard is a leading manufacturer of refrigeration components, including condensers. The company offers two types of condensers: conventional copper tube and fin type, as well as micro-channel type.

The conventional copper tube and fin type condenser has several advantages. Firstly, it is highly efficient in transferring heat due to the large surface area created by the fins. Secondly, it is durable and resistant to corrosion thanks to the inherent properties of copper. Finally, it is easy to maintain and repair, making it a popular choice for many refrigeration applications.

In addition to the conventional type, Boyard also offers micro-channel condensers. These are made up of multiple parallel channels that are much smaller than those in the conventional type. This design allows for better thermal performance and reduces the amount of refrigerant needed, making it more environmentally friendly. Moreover, Boyard has the capability to customize these condensers based on specific customer requirements.

Overall, Boyard’s condenser products offer high efficiency, durability, and flexibility to meet various refrigeration needs.

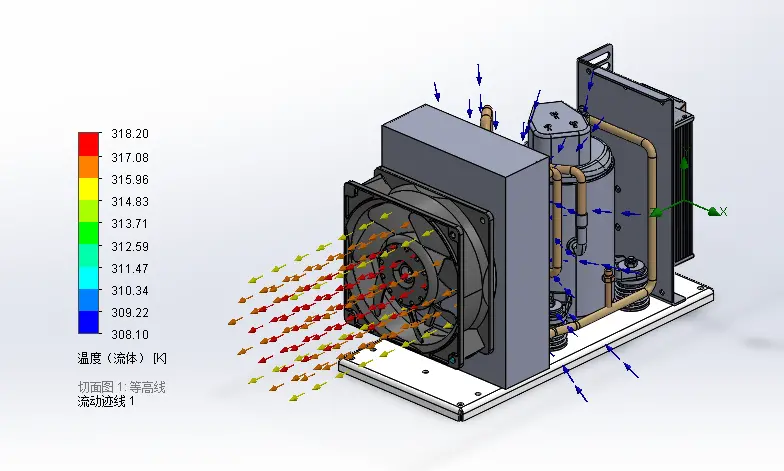

Fan

The Boyard compressor unit is equipped with fans that play an important role in the cooling process. The fans draw in ambient air and direct it over the condenser coils, where heat from the compressed refrigerant is released into the atmosphere. This process helps to maintain optimal operating temperatures for the system and ensures efficient performance.

To ensure reliable operation, it is important to regularly inspect and maintain the fans in a Boyard compressor unit. This includes cleaning the blades and motor housing to remove dirt and debris, checking for any signs of wear or damage, and lubricating the bearings as needed. Proper maintenance not only extends the lifespan of the fans but also helps to prevent downtime and costly repairs.

Reservoir

The Boyard compressor unit’s reservoir is located between the condenser and evaporator and is used to store high-pressure sub-cooled liquid. This storage tank, also known as an accumulator or receiver, serves as a critical component in maintaining stable system pressure.

The design of the reservoir includes safety features such as a pressure relief valve to prevent over-pressurization of the system. Additionally, it contains several ports for connecting to other components, including the compressor, pressure switch, and gauges.

With its strategic placement between the condenser and evaporator, the reservoir plays an important role in ensuring efficient and reliable operation of the Boyard compressor unit. By storing high-pressure sub-cooled liquid, the reservoir helps optimize the refrigeration cycle and maintain consistent system pressure.

Gas-liquid separator

The gas-liquid separator in the Boyard compressor unit is located between the evaporator and compressor to prevent liquid slugging. Its primary function is to separate the refrigerant into its liquid and vapor phases before it enters the compressor.

Liquid slugging occurs when liquid refrigerant enters the compressor, causing damage to the compressor components due to the inability to compress liquids. The gas-liquid separator allows the refrigerant vapor to pass through while trapping any liquid droplets.

In addition to preventing liquid slugging, the gas-liquid separator also helps to improve system performance and efficiency by ensuring only vapor enters the compressor, which is easier to compress. It also helps to protect other system components, such as the expansion valve and evaporator, from damage caused by liquid refrigerant.

Valves (The unit can be replaced with some optional parts according to customer’s requirements.)

Dry filter

It can effectively absorb the moisture in the refrigeration system and filter the impurities in the system to ensure the normal operation of the system.

Pressure protector

It is a device to keep the normal operation of the refrigeration system. When the condensing pressure and evaporation pressure in the system exceed the service limit of the compressor, the compressor is shut down through the pressure protector.

Condensing pressure controller

It can be installed for the start – stop control of condensing fan. The condenser pressure controller regulates the pressure in the condenser to maintain optimal performance and efficiency of the refrigeration system.

Solenoid valve

When the compressor stops, the solenoid valve is closed and the liquid refrigerant on the high pressure side is cut off to prevent the liquid refrigerant from migrating to the evaporator after the compressor stops and causing liquid compression when the compressor starts next time.

Spray valve

It is used to cool the compressor when the compressor temperature is high to prevent the compressor from overheating.

Sight glass

Low–pressure sensor

It detects low pressure value for unit adjustment control and system protection.

Oil separator

It separates the mixture of high temperature and high pressure refrigerant and refrigerant oil discharged from the compressor, and the separated refrigerant oil is stored at the bottom of the oil.

Throttling mechanism

Through the thermal expansion valve, electronic expansion valve or capillary, the liquid refrigerant on the high pressure side becomes low temperature and low pressure refrigerant through the throttling structure into the evaporator to absorb indoor heat.

Stop valve

It can manually control the refrigerant in the system through the stop valve.