Boyard specializes in providing cutting-edge compressor and HVAC system solutions, including the versatile mini chiller units. These mini chillers are specifically designed to meet cooling requirements in constrained spaces, catering to diverse applications such as medical devices, laboratory equipment, and heat-generating electronics/ machines/ batteries.

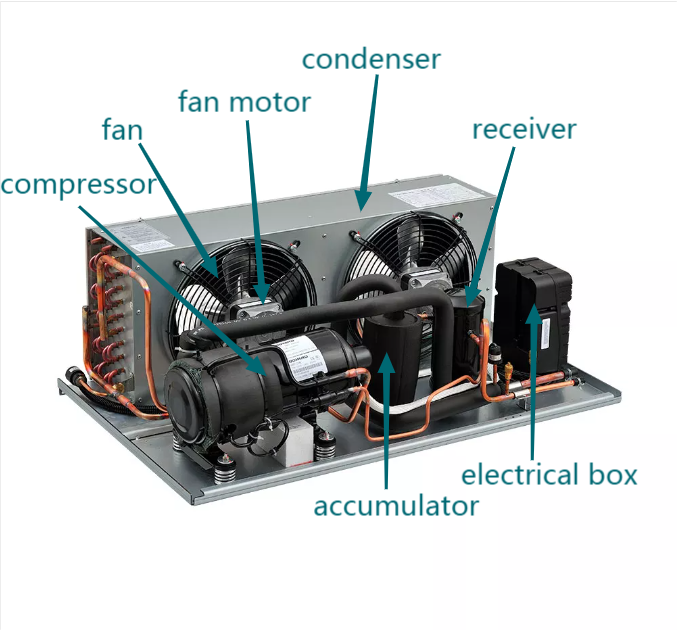

The primary function of a mini chiller is to effectively dissipate heat and maintain a constant low temperature. This is achieved through the circulation of liquid coolant, employing methods like direct evaporation or expansion to extract heat from surfaces or through air cooling. By ensuring precise temperature control, mini chillers safeguard against overheating and optimize system performance. In addition to conventional AC power, these systems are available in DC power variants such as DC 12V, DC 24V, or DC 48V, widening their compatibility with different setups.

Miniature cooling units boast several design specialties, such as compact dimensions, efficient heat transfer capabilities, low operational noise, and superior temperature control. Moreover, these energy-efficient units seamlessly integrate into various systems and can be customized with adjustable temperature settings, corrosion-resistant materials, and advanced remote monitoring functionalities.

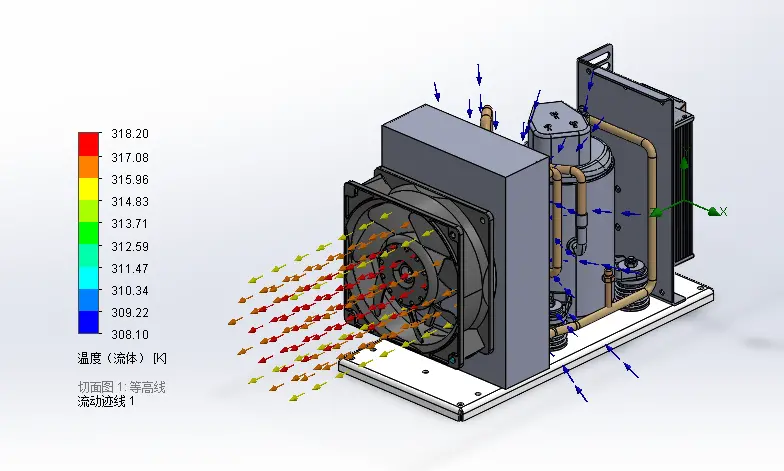

As a trusted provider, Boyard offers a comprehensive range of mini chiller solutions suitable for diverse applications, including medical devices, biochemical equipment, laser machines, laser projectors, battery thermal management, and personal cooling needs. Our experienced engineers collaborate closely with customers, validating cooling capacity requirements and simulating airflow and direct cooling heat transfer within the system to achieve optimal performance. Rigorous testing and failure mode analysis are incorporated at every stage from design to mass production, ensuring reliable performance and risk prevention.

Choose Boyard for top-notch mini chiller and miniature cooling unit solutions, combining advanced technology, robust design, and extensive application expertise.

Products Feature

- High reliability

a)Risk prevention design philosophy

b)20 years HVAC system manufacturing experience

c)Strict 100% online test of performance and leakage

d)Strict components sourcing - Various cooling method

a)Direct expansion

b)Liquid chiller

c)Air chiller - Compact and High efficiency

a)Design within limited space

b)Variable speed DC miniature compressor provide large capacity - Lower noise and vibration

a)Special design features to minimize vibration and noise

b)In bigger series, twin cylinder DC compressor available - Various Power supply

a)DC 12V,DC24V,DC48V,DC96V,DC312V

b)AC 220V 50 Hz, 115V 60Hz

Why choose us?

- Company Reliability

1.We are original factory!

2.Audit or plant tour is welcomed, online tour available

3.Provide HVAC solution to Haier Carrier, Panasonic, Daikin, Webasto etc. - Turn Key Technical Service

Boyard provide professional technical service like

1.System customization and simulation

2.Validation test: Capacity/ NVH

3.Controller matching and test

4.Mainboard matching service - OEM/ODM Customization

1.Boyard provide fast and reliable customization and validation service

2.Effective communication, online meeting available - Manufacturing Capacity

1.Specialized in HVAC, Boyard has ISO9001, ISO 16949 certificate

2.Capacity of 300K units per year - HVAC Experience:

1.3rd decades since entering HVAC industry

2.Provide HVAC solution to all kinds of application like mobile cooling/medical cooling/ machine cooling specialized air conditioner / thermal control system. Rich know-how - Fast Delivery

1.Sample within 30 days

2.Order delivery within 30 days - Warranty Assurance

1.24 months warranty

2.Technical support from company after purchase

Q&A:

Q: What are the key features of mini chiller products?

A: Mini chiller products offer high reliability, various cooling methods (direct expansion, liquid chiller, air chiller), compact and high efficiency design, and compatibility with various power supply options.

Q: What is the working principle behind mini chillers?

A: Mini chillers operate by circulating liquid/ air/ refrigerant through system to absorb and remove heat. This can be done through methods such as direct expansion, where the refrigerant expands directly in the system, or through liquid chilling, air chilling, or a combination of these methods.

Q: How does the risk prevention design philosophy contribute to the reliability of mini chiller products?

A: The risk prevention design philosophy ensures that potential issues are identified and addressed during the design phase, resulting in enhanced reliability and performance of mini chiller products.

Q: Can you provide customization options for mini chiller systems?

A: Yes, we offer professional technical support for system customization and simulation according to specific requirements. Our aim is to tailor the mini chiller system to meet your unique needs.

Q: What kind of technical support is provided after purchasing mini chiller products?

A: We provide 24 months of warranty for our mini chiller products, along with ongoing technical support to assist you with any queries or concerns that may arise.

Q: How do you ensure the efficiency of mini chiller products?

A: We calculate, simulate and validate by testing to ensure efficiency in every project.

Q: Can you share your manufacturing capacity and industry experience?

A: With over three decades of industry experience, we specialize in HVAC solutions. Our manufacturing capabilities are backed by ISO9001 and ISO 16949 certifications, and we have served esteemed brands such as Haier, Carrier, Panasonic, Daikin, Delta and Webasto.

Q: How long does it take for sample delivery and order fulfillment?

A: We strive to ensure prompt delivery. Sample products will be delivered within 30 days, while order fulfillment typically takes around 30 days as well.

Q: Is OEM/ODM customization available for mini chiller products?

A: Yes, we offer fast and reliable OEM/ODM customization services. Effective communication is maintained throughout the process, with online meetings available for seamless collaboration.

Q: How are system noise and vibration minimized in mini chiller products?

A: Our mini chiller products undergo meticulous pipeline design to minimize system noise and vibration. Also we have system can simulate the vibration. Plus we have experienced engineer who has been designing low vibration and noise units for vehicles air conditioner and indoor commercial refrigeration. These ensures a quieter operation and improved overall performance.

Q: Why miniature chillers are often designed to be powered by DC (direct current) power sources? Here are several reasons:

A: 1. Portability: DC power sources, such as batteries or solar panels, provide portability and flexibility. Miniature chillers powered by DC can be used in remote locations, outdoor settings, or on-the-go applications where AC power sources may not be readily available.

2. Efficiency: DC-powered chillers can be more energy-efficient compared to AC-powered chillers, especially when using high-efficiency DC compressors and motors. This can be beneficial for applications where energy conservation is a priority, like driven by lithium battery.

3. Compatibility: Many electronic devices and small appliances operate on DC power. Using DC power for miniature chillers ensures compatibility with existing power sources in electronics or small equipment without the need for additional converters or adapters. Such us laser application, laser system usually are 48V

4. Safety: DC power can be safer for certain applications, especially in environments where electrical safety is a concern. DC power is less likely to cause electric shocks and may be preferred for certain specialized applications. Voltage under 48V would be preferred in most of circumstances due to this concern.

Q: How can I customize a mini chiller system to meet my specific requirements?

A: We provide professional technical support for system customization. Our experienced engineers collaborate closely with you to understand your needs and tailor the mini chiller system accordingly, ensuring it aligns with your specific application and performance requirements. Contact us and give your detailed requirements, that is the start of our cooperation.

Q: How can I obtain a sample of your mini chiller product?

A: To request a sample, please reach out to our sales team. They will guide you through the process and provide you with the necessary information to proceed. Sample delivery typically takes around 30 days, subject to availability.

Q: What is the lead time for sample production?

A: Our standard lead time for sample production is approximately 30 days, depending on the complexity of the product and current production schedule. We strive to deliver samples in a timely manner to meet your project timeline.

Q: Can you provide an overview of the lead time for bulk orders?

A: The lead time for bulk orders may vary based on factors such as order quantity and product customization. We work closely with our clients to provide accurate lead time estimates during the ordering process, ensuring efficient production and delivery.

Q: How can I ensure a successful customization process for my mini chiller system?

A: To ensure a successful customization process, we recommend providing as much detailed information as possible about your requirements, including performance specifications, operating conditions, and any specific system integrations. This information enables our engineers to design and customize the mini chiller system accurately. We have a form to be filled by you as critical criteria of customer input.

Q: Can I consult with your technical team during the customization process?

A: Certainly! Our technical team is available for consultation throughout the customization process. We understand the importance of clear communication and collaboration to meet your unique needs effectively.

Q: Are there any minimum order quantity requirements for customized mini chiller systems?

A: Depending on the specific requirements and complexity of the customization, there might be minimum order quantity (MOQ) considerations. Normally customization start with annual quantity 500 pcs.

Q: How can I get more information about the technical specifications and performance of your mini chiller products?

A: For detailed technical specifications and performance data, please contact our sales team. They will be happy to provide you with comprehensive information, answer any additional questions you may have, and assist you in finding the right mini chiller solution for your needs.

Q: Are there any additional engineering costs associated with customizing a mini chiller system?

A: The engineering costs for customization may vary depending on the complexity of the modification/ designing required. Our sales team can provide you with detailed information regarding any associated engineering costs during the customization process. There is also a refund policy after reaching certain purchase quantity.

Q: Do your mini chiller products have the necessary certifications such as CE or UL?

A: Yes, our mini chiller products meet the necessary certifications, including CE and UL. For specific project, customer would bear the cost in the beginning. You may discuss the details of the cost and refund policy after reaching certain purchase quantity with sales team.

Q: Are there any additional certificates or compliance standards that your mini chiller products meet?

A: In addition to CE and UL, our mini chiller products may also comply with other relevant certificates and standards, such as ISO 9001 for quality management systems. Our sales team can provide you with specific information on the certifications and compliance standards that our products meet.

Q: Can you provide documentation and test reports for the certifications obtained by your mini chiller products?

A: Yes, we can provide documentation and test reports for the certifications obtained by our mini chiller products. These documents verify compliance with the applicable standards and demonstrate the quality and safety aspects of our products like ROHS and REACH.

Q: Are your mini chiller products compliant with environmental regulations and energy efficiency standards?

A: Yes, our mini chiller products are designed to comply with environmental regulations and energy efficiency standards. Like ROHS and REACH are available, also passed ISO14001 certificate.

Q: Can I request specific performance data or efficiency ratings for your mini chiller products?

A: Absolutely! We can provide you with specific performance data, efficiency ratings, and technical specifications for our mini chiller products. Please reach out to our sales team, and they will assist you in obtaining the information you need for your project evaluation and requirements.

Q: Can I nominate specific parts or components to be included in the mini chiller system?

A: Partially yes. While we offer a range of standard components that are optimized for performance and reliability, we understand that some customers may have specific preferences or requirements for certain parts. We evaluate the feasibility of incorporating nominated parts on a case-by-case basis, considering factors such as compatibility, performance, and overall system integrity.

Q: What is the process for requesting the inclusion of nominated parts in the mini chiller system?

A: If you have specific parts that you would like to be included in the mini chiller system, please provide us with the relevant information and specifications. Our technical team will carefully assess the suitability of the nominated parts and determine if they can be integrated into the system without compromising performance or safety.

Applications

Boyard’s miniature chiller units are used in a variety of applications, including EV Charge, Laser, Battery, Medical, Electronics and Life Science.